When managing your inventory, having the right products at the right time is essential. But if you’re relying on guesswork or outdated methods to forecast demand, you’re likely facing overstocks, stockouts, or both.

Poor forecasting leads to lost sales, wasted storage, and a whole lot of stress.

The Problem:

Inaccurate Demand Forecasting Hurts Inventory Management

Research shows that 43% of small businesses miss out on revenue opportunities due to poor inventory management (Wasp Barcode Technologies). When forecasting is off, you end up with too much stock gathering dust or not enough to meet customer demand.

Not only does this lead to cash flow problems, but also wasted space and lost customers.

The Solution:

AI-Driven Predictive Analytics with Bundle

Bundle’s AI-driven predictive analytics takes the guesswork out of forecasting. We analyse historical data and current trends to give you a clear view of future demand. You can maintain optimal inventory levels, reduce excess stock, and avoid stockouts with accurate insights.

It’s all about having the right amount of inventory, at the right time.

Accurate Insights

Use data-driven insights to understand customer demand patterns and make precise inventory decisions.

Reduced Waste

By aligning inventory levels with actual demand, you’ll minimise overstock and reduce waste.

Better Cashflow

Free up capital by keeping only what’s needed, improving cash flow and operational efficiency.

Example 01

Retailer Managing Seasonal Demand

We work with a retailer that struggled to predict demand for seasonal products, leading to excess stock in some locations and shortages in others. With Bundle, they analysed sales data across seasons to create precise demand forecasts. This reduced waste by 23% and ensured they always had the right products available when needed.

Example 02

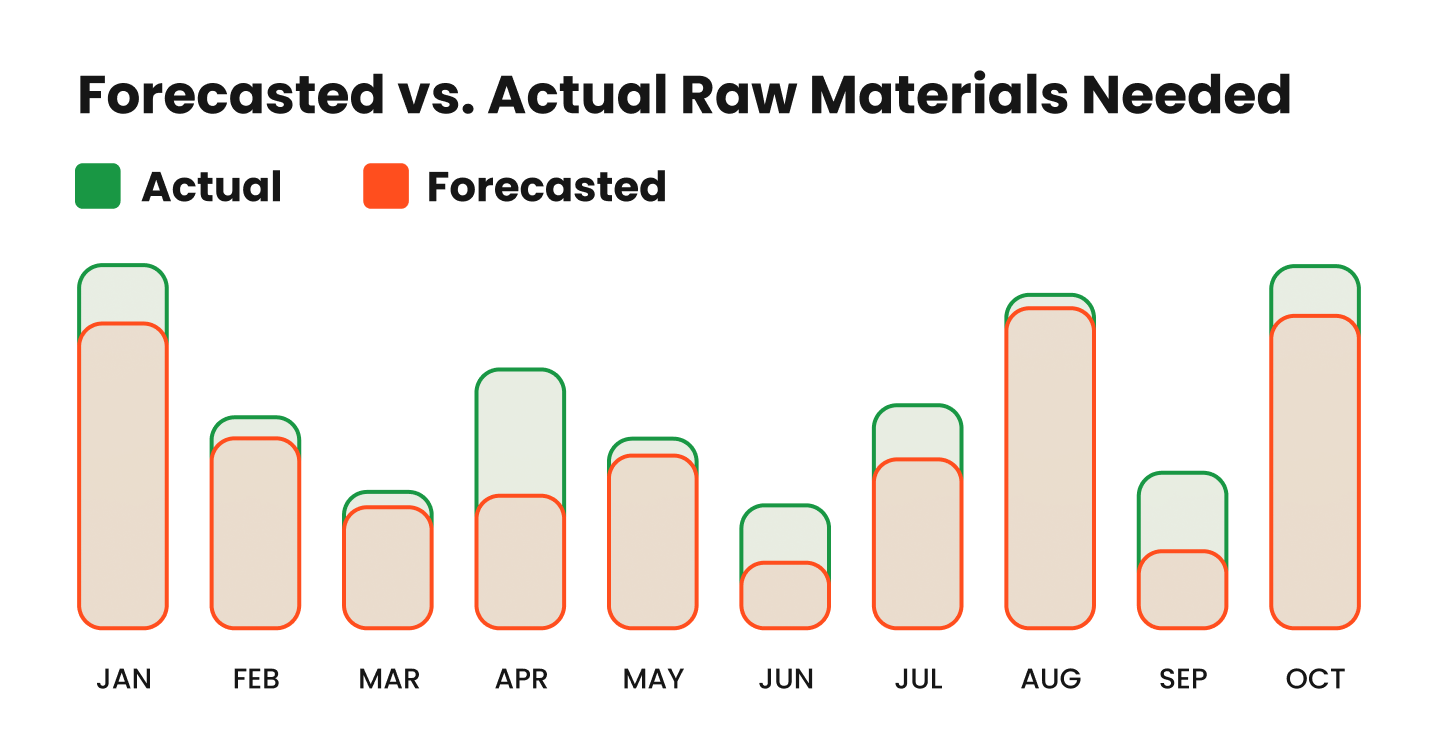

Optimising Raw Material Supply

We worked with a company that always faced production delays due to inaccurate raw material forecasts. Our predictive analytics helped them plan ahead by analysing trends in order volume and supplier timelines, reducing stockouts and improving production efficiency.

Example 03

Balancing High-Volume Inventory

One of our clients was experiencing fluctuating demand for high-volume items, which caused them to be frequently overstocked. Our insights allowed them to maintain leaner inventory levels while meeting demand spikes, reducing storage costs by 18% and improving fulfilment times.

If inaccurate demand forecasting is costing you money and efficiency, let’s chat about how Bundle can help you stay on top of inventory needs with AI-driven insights.

Want to unlock the true potential in your data?

There’s a Bundle for that!

Seeing is believing! Book a demo today to discover how easy it is to get started with Bundle.